Sealless Chemical Transfer for Corrosive and Hazardous Fluids

Magnetic centrifugal pumps in polypropylene (PP) and PVDF deliver leak-free performance for demanding industrial applications. By eliminating the mechanical shaft seal, these pumps reduce the risk of chemical leaks, lower maintenance requirements, and improve safety when handling acids, alkalis, solvents, and aggressive process fluids.

Key Features

- Sealless magnetic drive design — no dynamic seal, no fugitive emissions

- Corrosion-resistant construction — PP for cost-effective broad chemical compatibility; PVDF for high-temperature and aggressive media

- Reduced maintenance — fewer wear parts, longer service intervals

- Improved safety — ideal for toxic, corrosive, or environmentally sensitive chemicals

Typical Applications

- Water and wastewater treatment (chemical dosing, pH control)

- Chemical processing and transfer

- Surface treatment and metal finishing (pickling, plating baths)

- Mining reagent transfer

- Food & beverage utilities (CIP chemical circulation)

Technical Considerations

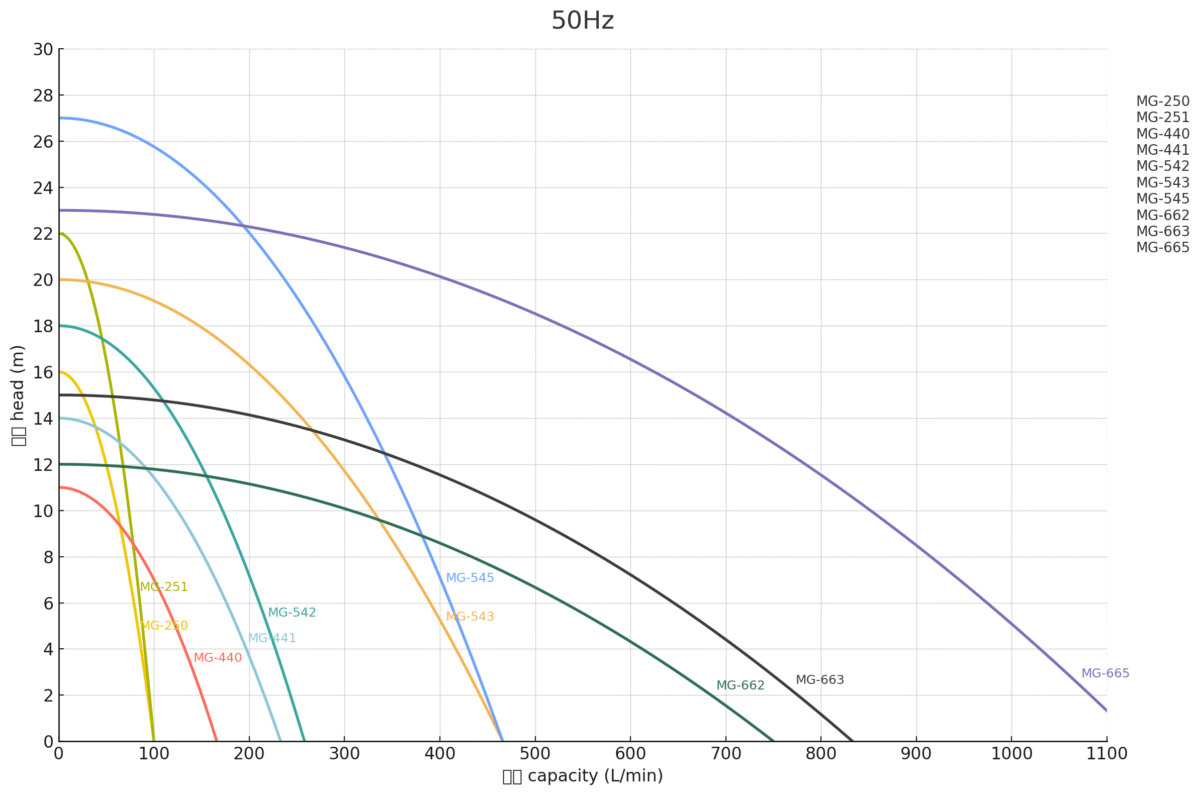

When specifying a magnetic centrifugal pump, provide fluid type, temperature, viscosity, required flow rate (GPM or L/h), total head, and duty cycle. Our engineering team will confirm material compatibility, recommend the correct model, and support installation and startup.

Why Choose Magnetic Drive Over Mechanically Sealed Pumps?

Magnetic drive pumps eliminate the most common failure point in chemical pumps—the mechanical seal. This results in higher uptime, lower lifecycle cost, and compliance with environmental and safety regulations related to emissions and operator exposure.

Need help sizing a pump for your application?

Share your process details—fluid, temperature, flow, and pressure—and our engineering team will recommend the optimal configuration within 24 hours.